La Palma - Fabrication BTS

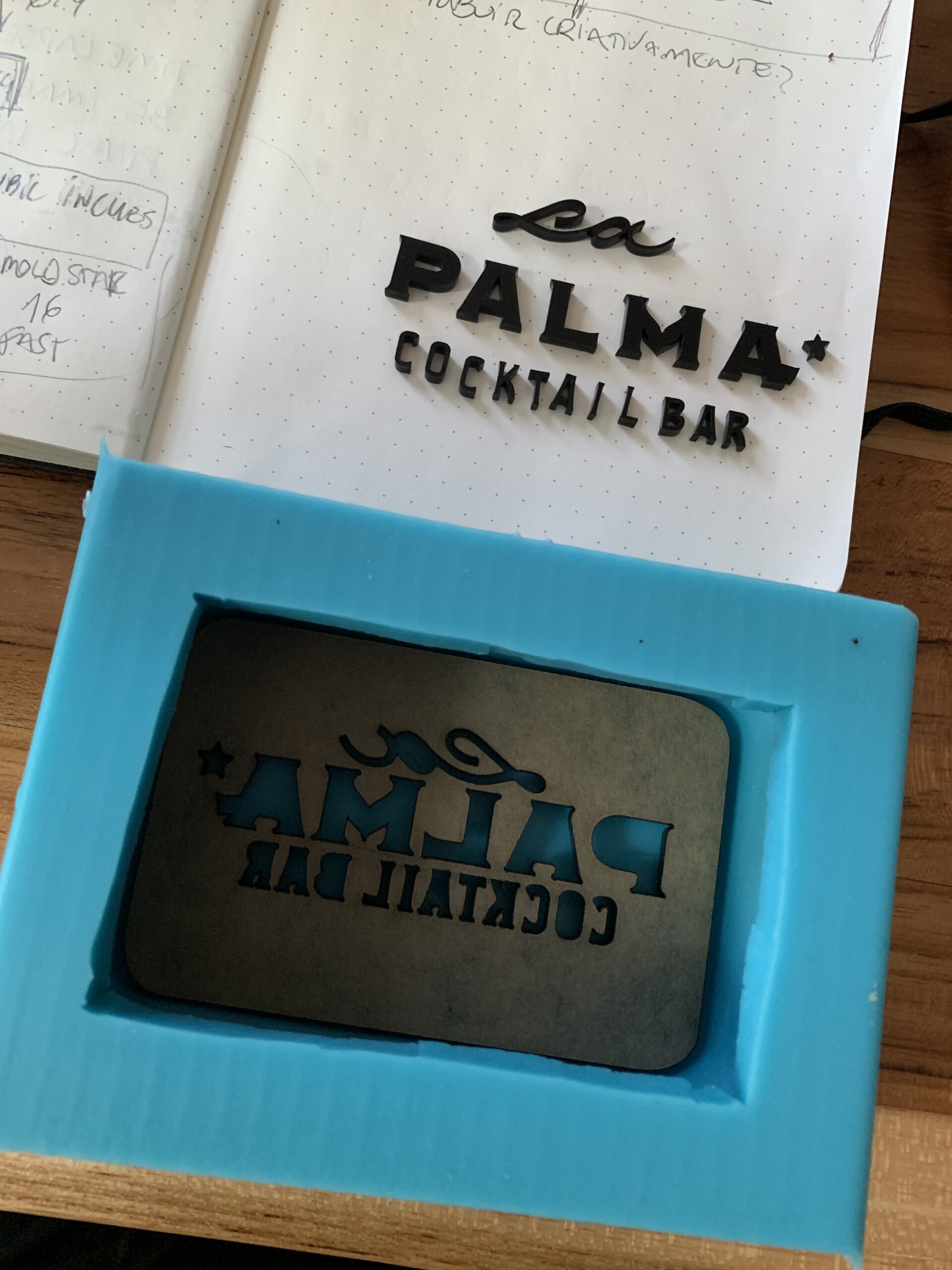

I created a custom soap prototype for

La Palma to be used on our photoshoot showcasing the design identity.

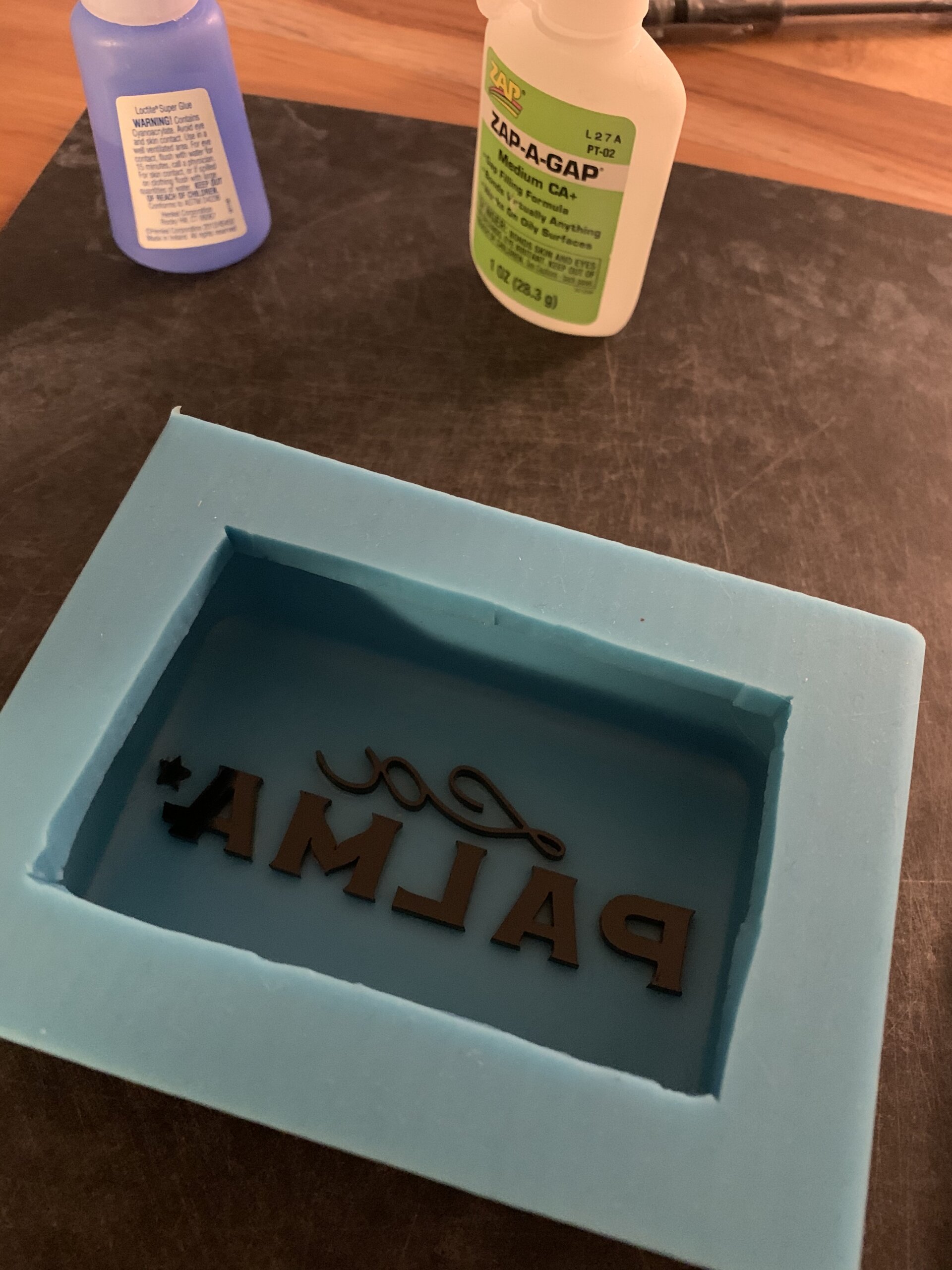

I've worked a lot with silicone molds in the past and in my opinion is the best way to create something with a "mass-produced" look.

The bas-relief logo in the soap was a small challenge but I quickly figured out how to glue the laser cut design to a blank soap mold.

Two molds had to be done in this process to get a master mold, from this master you can cast the soap in any material and make as many copies as necessary since the mold stays intact after every casting to stay true to the product we used real soap for this casting.

In this project we created 2 versions of the master mold.

Check the project page here.